OCEAN MATERIAL | JUL 19TH 2024 | 15 MIN

Table of Contents

Plastic pollution is one of our most pressing environmental issues, with devastating consequences for our planet. Every year, millions of tons of plastic waste end up in our oceans, rivers, and landscapes, causing severe harm to wildlife and ecosystems. It’s estimated that over 100,000 marine mammals and one million seabirds die each year due to plastic pollution.

The problem starts on land, where inadequate waste management and careless disposal lead to plastic debris entering waterways. Once in the ocean, plastics can persist for hundreds of years, breaking down into smaller particles known as microplastics. These microplastics are ingested by marine life, entering the food chain and ultimately impacting human health.

The visual blight of plastic waste is just the tip of the iceberg. Beneath the surface, plastics release toxic chemicals that can disrupt biological processes in animals and humans. This widespread pollution also threatens tourism, fishing, and other industries reliant on clean, healthy oceans and natural environments.

However, the story doesn’t have to end in despair. Recycling plastic is a powerful way to combat this crisis. By reprocessing plastic, we can reduce the amount of waste that pollutes our planet, conserve natural resources, and create a more sustainable future. This article will guide you through the types of plastics that can be recycled and how you can make a difference.

Understanding Plastic Recycling

Recycling is the process of converting waste materials into new goods, significantly reducing the need for raw resources and minimizing environmental impact. This process is particularly crucial for plastics, which are ubiquitous in modern life but pose significant environmental challenges when disposed of improperly.

Plastic recycling involves several key steps to transform discarded items into reusable materials:

- Recyclable items are gathered from various sources, including homes, businesses, and industries, through programs like curbside pick-up and drop-off centers.

- Once collected, items are sorted by type and color. Advanced facilities use technologies like optical sorting and artificial intelligence to efficiently separate different types.

- The sorted materials are cleaned to remove contaminants such as residue, labels, and adhesives, ensuring the quality of the material.

- Cleaned items are shredded into small pieces, making them easier to handle and process.

- Melting and Reprocessing. The shredded pieces are melted and reformed into new shapes through methods like extrusion, injection molding, and blow molding.

- In some cases, the melted material is cooled and cut into small pellets, which can be used as raw material for manufacturing new things.

In theory, almost every type of plastic can be recycled. However, when something is made of different types of plastics or is contaminated with food or other substances, recycling becomes difficult and costly. Additionally, sustaining a recycling facility requires significant financial investment. But don’t worry! Organizations like ours work tirelessly to overcome these challenges for a better future of the planet.

So, let’s proceed and find out what plastic numbers are recyclable!

What Types of Plastic are Recyclable

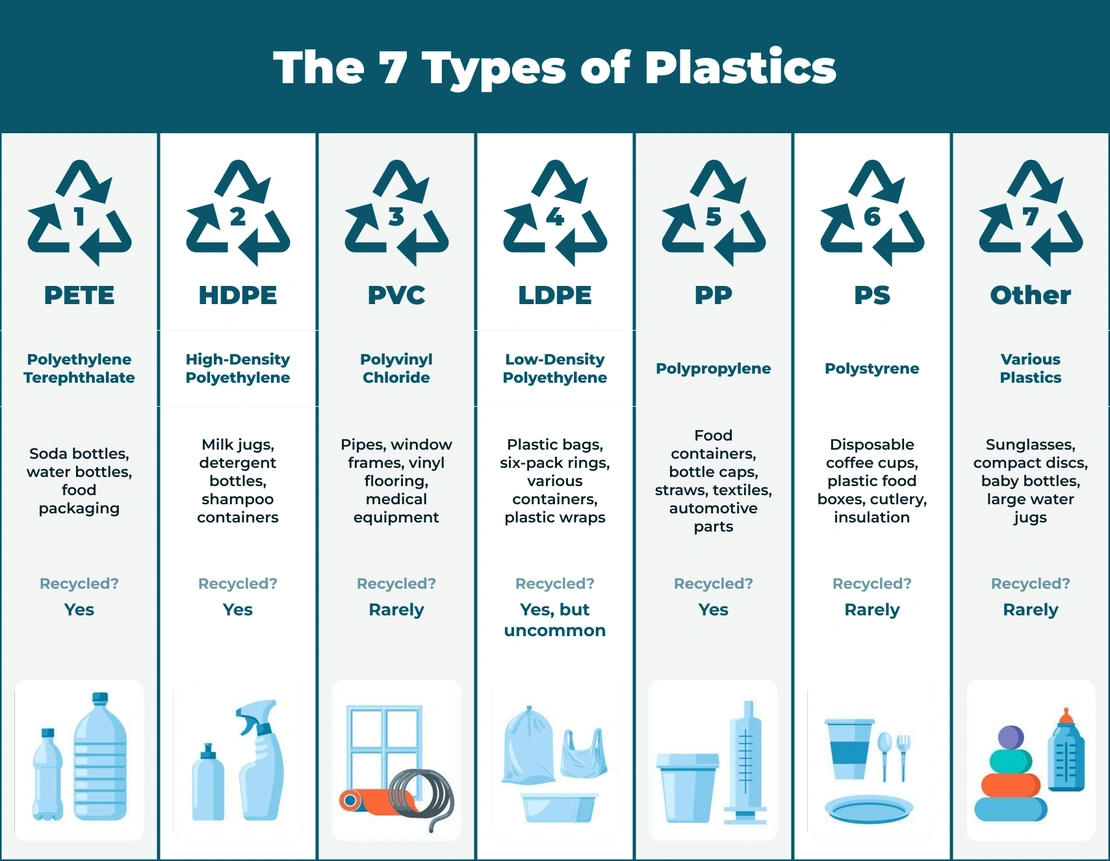

Many people are questioning what the recycling numbers 1-7 mean and which plastics can be recycled. Let’s investigate each number and find out which plastics are recyclable.

PET (Polyethylene Terephthalate, Code 1) Plastic

Polyethylene Terephthalate, commonly known as PET or PETE, is one of the most widely recycled plastics. This type is found in numerous everyday items, from soda and water bottles to packaging. PET is favored for its strength, thermo-stability, and transparency, making it ideal for packaging a variety of consumer goods.

The process of repurposing PET is relatively straightforward and efficient. Collected bottles are cleaned, shredded into small flakes, and then melted to produce new materials. Remarkably, PET can undergo this process multiple times without significant loss of quality. This feature makes it particularly valuable in reducing plastic waste and conserving resources.

In the United States, approximately 31% of PET bottles find their way back into the production cycle, while Europe boasts a more robust 52% recycling rate.

PET holds the title of the most repurposed plastic globally, supported by a widespread infrastructure for its collection and processing.

Once PET is processed, it transforms into a variety of new products. One of the most common uses is in creating new bottles, forming a closed-loop system that minimizes waste. Additionally, PET fibers are spun into textiles, making clothing items like T-shirts and sweaters. In fact, it takes about ten PET bottles to produce a single T-shirt.

Beyond textiles, PET is also good for manufacturing carpeting and upholstery, showcasing its versatility. Its use extends to packaging materials as well, such as clamshell containers for fresh produce and takeout meals.

Processing one ton of PET containers can save 7.4 cubic yards (impressive, isn’t it?) of landfill space and significantly reduce greenhouse gas emissions.

HDPE (High-Density Polyethylene, Code 2) Plastic

High-density polyethylene, or HDPE, is known for its robustness and resistance to impact, making it a preferred material for products like milk jugs, detergent bottles, and shampoo containers. HDPE is not only strong and durable but also highly resistant to both high and low temperatures, enhancing its versatility.

HDPE is the second most recycled plastic after PET, thanks to its widespread use and high recovery rate.

The journey of HDPE through the recycling process is quite fascinating. Collected HDPE products are cleaned and ground into small pellets or flakes. These are then melted down and molded into new products. HDPE’s structure allows it to be repurposed into a variety of new items without significant loss of quality, ensuring its continued utility.

Approximately 30% of HDPE bottles are recycled in the United States.

rHDPE is incredibly versatile and finds its way into numerous new products. One of the most common uses is in the production of new containers for non-food items, such as detergent and shampoo bottles. Additionally, HDPE is utilized to create durable plastic lumber, which is a popular material for outdoor decking, fencing, and playground equipment.

Another innovative use of rHDPE is in the creation of piping systems. These pipes are utilized in various applications, including irrigation, drainage, and even gas distribution. HDPE’s strength and durability make it an ideal material for these purposes, ensuring longevity and reliability.

Recycling HDPE significantly reduces the carbon footprint compared to producing new HDPE from raw materials. Each ton of rHDPE saves about 1.8 tons of CO2 emissions.

PVC (Polyvinyl Chloride, Code 3) Plastic

Polyvinyl Chloride, commonly known as PVC can be found in both rigid and flexible forms. Rigid PVC is often utilized in construction materials such as pipes, window frames, and siding, while flexible PVC is utilized in products like cables, medical equipment, and clothing. This type is not commonly recycled.

In the US, a significant portion of PVC ends up in landfills.

- The production and disposal of PVC can release harmful chemicals, including dioxins, which are toxic to both the environment and human health.

- PVC often contains additives and contaminants that complicate the recycling process and reduce the quality of recycled materials.

- Many recycling facilities do not accept PVC due to these complexities, resulting in lower recycling rates.

PVC can be harmful to the environment if not properly managed, releasing toxic substances during its life cycle.

If PVC is actually recycled, it is utilized to make construction materials such as piping and fittings. It is also utilized in creating flooring and roofing tiles.

LDPE (Low-Density Polyethylene, Code 4) Plastic

Low-density polyethylene, or LDPE, is a type of plastic known for its flexibility and durability. It is commonly applied in the production of items like plastic bags, six-pack rings, various containers, dispensing bottles, and well-known plastic wraps. LDPE is characterized by its low-density molecules, giving it a thinner and more flexible design compared to other plastics like HDPE. This material is often one-purpose use.

LDPE is not commonly recycled, and several factors contribute to this:

- Recycling Infrastructure. LDPE recycling is less widespread compared to other plastics like PET and HDPE. Many municipal recycling programs do not accept LDPE because it tends to tangle in recycling machinery, causing disruptions and additional maintenance.

- Economic Viability. The lightweight and low-density nature of LDPE makes it less economically viable to collect and process compared to heavier plastics. The cost of recycling it often outweighs the benefits, leading to lower recycling rates.

- Contamination Issues. LDPE is often contaminated with food residues and other substances, complicating the recycling process and reducing the quality of the recycled material.

Sadly, most LDPE ends up in landfills or as environmental litter.

But when LDPE is actually successfully recycled, it can be transformed into a variety of new products. One of the most common applications is in the production of bin liners and trash bags, providing a practical use for the material. Additionally, LDPE can be repurposed into plastic lumber, which is utilized for outdoor decking, furniture, and playground equipment. This durable and versatile material offers a sustainable alternative to traditional wood.

Furthermore, recycled LDPE is often applied to create packaging films, which are essential for products that require flexible and lightweight packaging solutions.

PP (Polypropylene, Code 5) Plastic

Polypropylene, commonly abbreviated as PP, is a versatile and durable plastic widely used in various products. Its resilience, high melting point, and resistance to many chemical solvents make it ideal for applications in packaging, textiles, automotive parts, and consumer goods.

PP is found in a multitude of everyday items. It’s commonly used for containers like yogurt cups, bottle caps, and straws due to its ability to withstand heat, making it suitable for both microwaveable and dishwasher-safe goods. Additionally, PP is applied in the production of textiles for ropes, thermal undergarments, and reusable shopping bags. In the automotive industry, it is utilized for parts such as battery cases and signal lights.

The process of repurposing PP involves collecting and sorting the materials, cleaning them to remove contaminants, and then melting and reforming them into new goods. Despite its widespread use, the recycling rate for PP is relatively low compared to other plastics. This is largely due to the complexity and cost associated with the recycling process.

PP is often contaminated with food residues and other substances, complicating the recycling process and reducing the quality of the recycled material.

The cost of recycling PP can be high due to the need for thorough cleaning and processing, which often makes it less economically viable compared to recycling other plastics.

Despite these challenges, recycled PP is often used in the production of automotive parts, reducing the need for new raw materials in this industry. Additionally, it can be used to create industrial applications such as plastic pallets, bins, and signal lights. In the textile industry, recycled PP fibers are used to make items like reusable bags and carpets.

PS (Polystyrene, Code 6) Plastic

Polystyrene, abbreviated as PS, is a plastic known for its versatility and is applied in a wide range of applications. It can be found in both solid and foam forms, making it suitable for various uses, from grocery containers to insulation materials.

PS is commonly used for disposable coffee cups, plastic boxes, cutlery, and packing peanuts. In its solid form, PS is utilized for items like CD and DVD cases, while the foam version (often known by the brand name Styrofoam) is good for thermal insulation, protective packaging, and lightweight architectural models.

Recycling PS plastic presents several challenges:

- Such plastic items, especially containers, are often contaminated with food residues, making the recycling process more difficult and reducing the quality of the recycled material.

- Foam PS is extremely lightweight and takes up a large volume, making it inefficient to transport and process. This high volume-to-weight ratio increases the costs and complexity of recycling.

- Same as some other types, the cost of collecting, cleaning, and processing PS often outweighs the benefits, resulting in a low recycling rate for this type of plastic.

PS is not biodegradable and can persist in the environment for hundreds of years. When disposed of improperly, it can break down into microplastics, which are harmful to wildlife and ecosystems.

PS can be repurposed in the production of items like picture frames, insulation sheets, rulers and trays. Additionally, it can be used to create durable building materials, including structural insulation panels and cement blocks. Unfortunately, this is rarely seen.

Other (Code 7)

The “Other” category, represented by recycling code 7, is a catch-all for various types of plastics that do not fit into the categories of codes 1 through 6. This group includes a wide range of materials:

- Polycarbonate (PC).

- Acrylonitrile Butadiene Styrene (ABS).

- Nylon (Polyamide, PA).

- Acrylic (Polymethyl Methacrylate, PMMA).

- Polylactic Acid (PLA).

- Polyurethane (PU).

- Multilayer Plastics.

Due to the diversity within this category, code 7 plastics are found in many different applications. For instance, polycarbonate is often used for durable items like eyewear lenses, digital discs (CDs, DVDs), and large water containers. Other plastics in this category might be used in automotive parts, medical devices, and even some types of containers.

The broad range of materials included in this category makes it difficult to develop standardized recycling processes. Each type of plastic requires different handling and processing techniques. Unfortunately, code 7 plastics are rarely recycled due to the complexity and cost associated with separating and processing the different materials. As a result, many of these items end up in landfills.

There are some rare and innovative uses for recycled code 7 plastics. For example, polycarbonate can be recycled into new plastic items, such as electronic casings, reusable water bottles, and even components for greenhouses. However, due to the complexity and cost, seeing these products is rare.

Here at Ocean Material, we pay attention even to Type 7 materials. We recycle ABS, PC, and PA6, ensuring that even these complex plastics find a new life instead of ending up in landfills.

ABS (Acrylonitrile Butadiene Styrene) Plastic

ABS is known for its strength, rigidity, and shiny finish. It is widely used in a variety of consumer products due to its durability and impact resistance.

Recycled ABS can be used to manufacture new consumer electronics housings, automotive parts, and durable goods such as kitchen appliances and LEGO bricks. The material retains much of the original ABS’s properties, making it ideal for creating sturdy and reliable items.

PC (Polycarbonate) Plastic

Polycarbonate is a tough, transparent plastic that offers high impact resistance and optical clarity. It is often used in applications where durability and clarity are essential.

Polycarbonate can be reused in the production of electronic components and reusable water bottles. Additionally, it is frequently utilized in construction materials, such as roofing panels and greenhouse glazing, due to its strength and transparency.

PA6 (Polyamide 6 or Nylon 6) Plastic

PA6, or Nylon 6, is a versatile engineering plastic known for its high strength, toughness, and resistance to abrasion and chemicals. It is common for textiles and industrial applications.

rPA6 is good for producing automotive parts, such as under-the-hood components and exterior parts. It is also good in the production of industrial components like gears and bearings, as well as in the textile industry for items such as carpets and clothing. The material maintains excellent mechanical properties, making it suitable for high-performance applications.

Recycling Numbers or Plastic 1-7 Chart

To make it easier for you, we prepared a chart of the 7 types of recyclable plastics. This will help you easily remember what each type is for and whether it can be recycled.

Conclusion

Even though plastic recycling isn’t as advanced as metal and glass recycling, our world is making significant progress each year. Advancements in recycling technologies and increased awareness of environmental issues are crucial for our planet’s health and sustainability.

At Ocean Material, we are committed to this. We recycle a variety of plastics, including those that fall under the challenging Type 7 category, like ABS, PC, and PA6. Our efforts turn waste into valuable resources, contributing to a more sustainable future.

If you are interested in saving the planet, we invite you to check out our products, all made from recycled plastic. Together, we can make a difference and drive the progress needed to protect our environment for future generations.

19.07.2024

FAQ

The main reasons why not all plastic is recycled involve complexity, contamination, and economic factors. Plastics are made from various resins, each requiring different processes, and some items combine multiple types of plastics, making them difficult to separate efficiently. Contamination with food, chemicals, or other substances also poses a significant challenge, as cleaning these plastics to a usable level can be both difficult and costly. Moreover, the economic viability of recycling certain plastics is often low; the costs of collecting, sorting, and processing can exceed the value of the material, particularly for lightweight and low-density.

You can look for the recycling symbol on the product, which usually appears as a triangle of arrows surrounding a number between 1 and 7. This number, known as the Resin Identification Code, indicates the type of plastic the item is made from. Generally, numbers 1 (PET) and 2 (HDPE) are widely accepted for recycling (more than others at least), while others may vary depending on local recycling programs. It’s important to check with your local recycling facilities to confirm which types of plastic they accept, as recycling capabilities can differ by region. If unsure, contacting your local recycling center can provide the most accurate guidance.