OCEAN MATERIAL | AUG 18TH 2023 | 9 MINS

Direct Processing of Seaweed into Polymer Material through Extrusion: A Sustainable Approach to Eco-Friendly Packaging

Ocean Material® often collaborates with passionate problem solvers who are dedicated to innovative solutions for ocean pollution. We had a conversation with Ludwig Schmidtchen, Head of the Seaweed Polymer Project at Brabender, who shared insights into a groundbreaking approach that aims to transform seaweed directly into polymer materials through extrusion. We’re excited to summarize this innovative concept in the following article.

Traditional polymer manufacturing processes, whether derived from fossil fuels or renewable resources, often come with a significant CO2 footprint due to their complex and resource-intensive nature. In contrast, nature has already developed efficient processes for polymer production. Algae, having evolved billions of years ago, possess the ability to synthesize polymers using sunlight, CO2, saltwater, and nutrients in a highly efficient manner. This natural polymer synthesis itself even results in a negative CO2 footprint as it actively absorbs CO2 from the atmosphere.

The Concept of Direct Seaweed-to-Polymer Extrusion

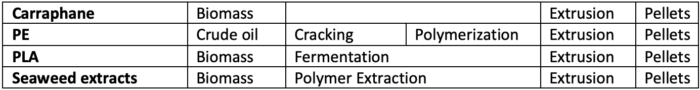

The idea behind this approach involves directly processing seaweed into polymer material through extrusion, effectively converting seaweed into desired products like pellets, strands, films, or 3D-moulded parts while retaining all the components of seaweed in the final product. The material is called Carraphane. This streamlined process minimizes the number of steps required for production, potentially leading to a significantly reduced CO2 footprint throughout the entire lifecycle of the material. The important advantage compared to other polymer materials is that the polymer synthesis is done by nature. Hence no external resource and energy intense polymer synthesis or extraction is necessary. The table shows the difference in processing for some known polymer materials:

Due to its simplicity and low raw material costs, seaweed-based polymer material not only offers an environmentally friendly alternative to certain plastics but also holds the promise of being economically competitive. The journey starts with the growth of seaweed in the ocean, where solar energy, seawater, CO2, and nutrients lead to the formation of a polysaccharide-rich seaweed biomass. After around 45 days of cultivation in aquacultures, the seaweed is harvested, containing about 85% water at that stage. The water content is then reduced through sun-drying, ensuring the seaweed remains storable without any issues.

A Sustainable Packaging Solution

From films to packaging for small technical parts, seaweed-based polymer materials open up possibilities for sustainable packaging solutions. Theoretically, these packaging materials can be recycled to produce new products directly or even converted into fertilizer, completing the circular economy loop. However, current recycling loops for seaweed-based packaging are yet to be established. In the absence of such recycling systems, the best option remains biological recycling with organic waste.

Towards Biodegradability and Water Resistance

While certification of biodegradability is still underway, the composition of seaweed-based materials, derived from natural components, suggests good biodegradability. Initial tests have demonstrated successful dissolution in water and home composting, further supporting the assumption of biodegradability. Ongoing efforts are being made to enhance the water resistance of the algae-based material, ensuring its versatility in various applications.

A Promising Future for Seaweed-Based Polymers

The direct processing of seaweed into polymer material through extrusion presents a promising avenue for sustainable and eco-friendly packaging solutions. As work continues to optimize the material and explore its potential applications, researchers and innovators are excited about the possibilities that seaweed-based polymers offer to reduce environmental impact and promote a more circular economy.

Through collaboration, Ocean Material® and Brabender are leading the way in this exciting, environmentally conscious research field. With ongoing advancements and growing awareness of sustainable alternatives, the future of eco-friendly packaging shines bright, with seaweed-based polymers at the forefront.

https://www.brabender.com/en/water-soluble-films-made-from-carraphane/

18.08.2023